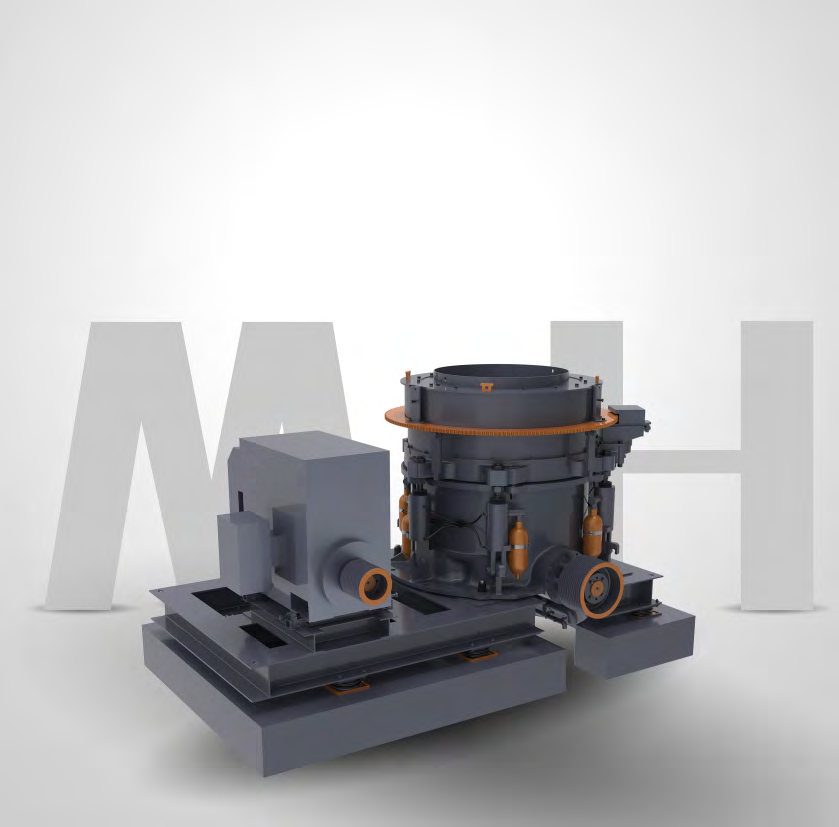

MG series single-cylinder hydraulic cone crusher

Product Description

single-cylinder hydraulic cone crusher

MG series single-cylinder hydraulic cone crusher is mainly suitable for medium and fine crushing operations of various scales of sandstone and ore processing projects. The series with "S" suffixed is mainly suitable for medium crushing operations, with larger feed size and larger processing capacity. The series without the suffix "S" are mainly suitable for medium and fine crushing operations. The MG series crushers have the advantages of low cost, compact structure, simple operation, and wide application range. It is equipped with automatic uniform feeding device, so that the materials can be uniformly formed in the special cavity. Therefore, the product has a better particle shape, all parts of the crusher can be hoisted from the upper part, and the replacement of wearing parts is convenient and quick. The intelligent automatic control system can adjust the size of the discharge port at any time through the touch screen and set the rated power and other parameters.

MG·Performance Characteristics

1. The most optimized eccentricity can preset a constant discharge gap;

2. The automatic and uniform feeding device makes the materials form uniform lamination and crushing in the special cavity; it has the characteristics of large throughput, high product output and good product shape;

3. Quick and easy replacement of wearing parts, easy adjustment of discharge port;

4. There are manual and PLME automatic control systems for users to choose.

|

Model |

Production capacity (TPH) |

Discharge port range (mm) |

Maximum feeding particle size (mm) |

Motor Power (kW) |

Equipment weight (t) |

|

MG100S |

80-250 |

20-45 |

250 |

75-90 |

7.35 |

|

MG200S |

110-430 |

25-50 |

295 |

110-160 |

10.9 |

|

MG300S |

180-495 |

25-50 |

330 |

132-250 |

16.2 |

|

MG500S |

300-950 |

45-80 |

440 |

200-355 |

33.3 |

|

MG7 |

350-1850 |

30-90 |

450 |

375-560 |

62 |

|

MG11F |

80-190 |

8-30 |

200 |

132-160 |

10.7 |

|

MG11M |

105-360 |

15-45 |

220 |

132-160 |

11.9 |

|

MG100 |

40-105 |

8-20 |

140 |

75-90 |

5.8 |

|

MG200 |

60-200 |

8-35 |

210 |

110-160 |

9.3 |

|

MG220 |

70-315 |

8-35 |

215 |

132-220 |

10.2 |

|

MG300 |

100-330 |

8-35 |

260 |

200-250 |

13.4 |

|

MG330 |

105-475 |

8-35 |

225 |

250-316 |

15.7 |

|

MG550 |

140-800 |

10-45 |

265 |

250-400 |

26.5 |

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English