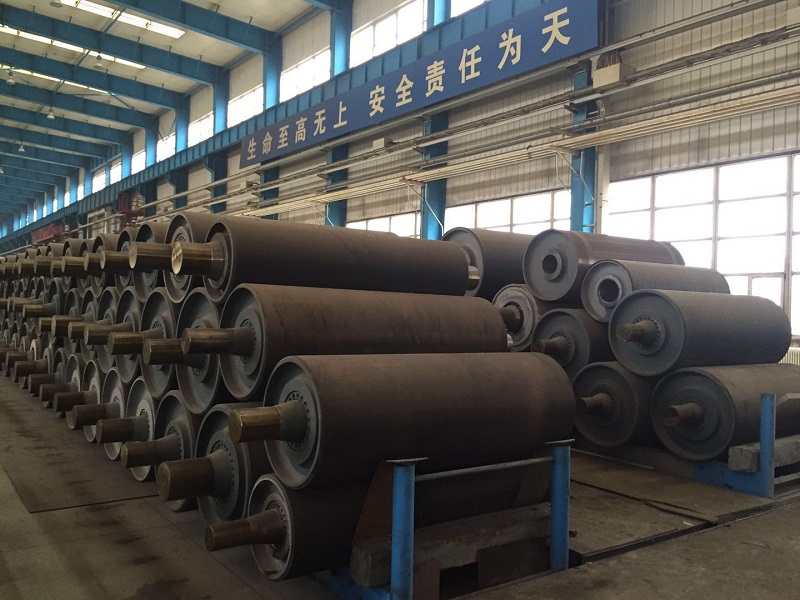

Pulley/Drum

Product Description

China Pulley manufacturers

China Drum suppliers

Pulley/Drum

The design and manufacture of the Pulley/Drum adopts the proprietary technology and equipment imported from Germany PWH company. The company has developed the finite element analysis and calculation software of the drum group, which improves the drum structure, reduces the structural stress, and improves the life and reliability of the drum.

The cylinder body of the drum adopts a fully welded structure, and the welding method of the connecting plate and the cylinder body is CO2 gas shielded welding and submerged arc automatic welding. After the cylinder is welded, ultrasonic or X-ray flaw detection is performed on the weld seam to ensure the welding quality; annealing treatment is performed to eliminate internal stress.

The drum shaft is a forging, and its allowable torque and allowable resultant force meet the design requirements. All shafts are non-destructively tested, ultrasonically inspected before machining and electromagnetically or permeable after machining. There should be no defects such as interlayers, folds, cracks, and scars.

The drum hub and the shaft are connected by expansion sleeve and key connection assembly.

The rubber layer on the surface of the drum is covered with vulcanized rubber, and the rubber layer is not allowed to have defects such as delamination and blistering. The physical and mechanical properties of the surface rubber and primer will comply with the relevant regulations in GB10595.

After the drum is assembled, the static balance test is carried out, and the precision reaches G40.

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English