Idler

Product Description

China Idler manufacturers

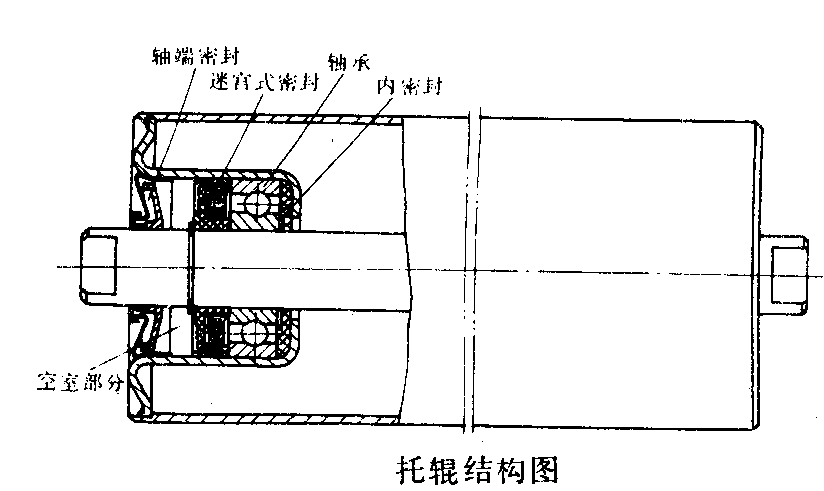

The idlers are designed and manufactured with proprietary technology and special equipment. The bearing seat and dust cover are stamped from high-quality steel plates. The idler body is made of high-frequency seam welded pipe with uniform wall thickness, high roundness and straightness. The stamped bearing seat and the idler roller body are welded by automatic carbon dioxide gas shielded welding. Bearings are special large clearance bearings for idlers. It adopts a 4-way combined sealing structure with good sealing performance, which has good waterproof and dustproof performance, and is especially suitable for dusty and rainy working environments. The roller bearings are lubricated with disposable long-lasting lithium-based grease. The service life of the idler under normal working conditions is not less than 30,000 hours, and the damage rate during the service life is not more than 10%. It has the characteristics of light weight, stable operation, flexibility, small resistance, low energy consumption, low noise and long service life. Its structure is shown in the figure below:

The rotational frictional resistance coefficient of the idler under laboratory conditions is 0.02~0.022.

The idler is produced by a production line composed of efficient special equipment, which realizes specialized production, including the production line of idler shaft, pipe body, sealing cover, bearing seat, idler assembly and so on.

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English