Horizontal Intensive Mixer

Product Description

Horizontal Intensive Mixer Suppliers

Cheap Horizontal Intensive Mixer

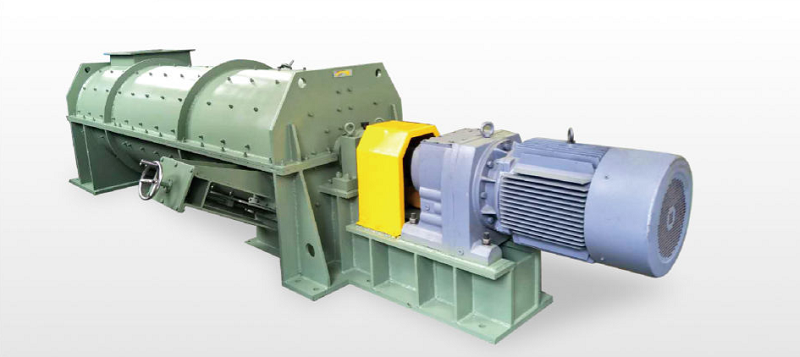

Horizontal Intensive Mixer, a horizontal forced mixer, is a mixing equipment widely used in industrial production. It is mainly used for rapid and uniform mixing of powders, granules, slurries, liquids and other materials.

Introduction of Horizontal Intensive Mixer

Horizontal Intensive Mixer consists of a horizontal mixing cylinder and a high-speed rotating mixing device inside the cylinder. Designed to handle large quantities of materials, this mixer provides efficient, uniform mixing. Its working principle is to quickly and powerfully stir and turn the materials through the internal stirring blades in a short time to achieve the purpose of mixing.

Features of Horizontal Intensive Mixer

1). High efficiency: The horizontal forced mixer has high mixing efficiency and can complete the mixing task in a short time.

2). Uniform mixing: Well-designed mixing blades ensure comprehensive mixing of materials and improve the uniformity of mixing.

3). Strong adaptability: able to handle the mixing of materials in different states (dry powder, wet slurry, liquid, etc.).

4). Easy to operate: Most horizontal forced mixers are equipped with automatic control systems, which simplifies the operation process.

5). Easy to clean and maintain: The design usually takes into account the convenience of cleaning and maintenance, and some models of mixers can also be quickly disassembled and assembled.

Advantages of Horizontal Intensive Mixer

1. Save time: Due to the high mixing efficiency, large quantities of materials can be mixed in a shorter time.

2. Energy saving and emission reduction: The efficient mixing process reduces energy consumption.

3. Improve product quality: Uniform mixing effect directly improves product quality and consistency.

4. Reduce labor costs: Automated control reduces the need for manual operations and reduces production costs.

Applications of Horizontal Intensive Mixer

Horizontal Intensive Mixer is widely used in chemical, pharmaceutical, food, building materials, powder metallurgy and other industries. For example, it is used in the chemical industry to mix different types of powders and additives; in the food industry it is used to mix various ingredients and spices, etc.

FAQ

Q: Can Horizontal Intensive Mixer handle liquid mixtures?

A: Yes, it can handle the mixing of materials in various states such as liquid, slurry and dry powder.

Q: How to choose the appropriate mixer model?

A: Choosing the appropriate model requires considering the type of mixed materials, batch size, mixing cycle and other factors. It is recommended to communicate with the manufacturer and provide detailed requirements.

Q: Is the cleaning and maintenance of the mixer complicated?

A: It depends on the model and design. Modern mixers are often designed with features that make cleaning and maintenance easier, such as quick-release construction.

Q: What is the price range of Horizontal Intensive Mixer?

A: The price depends on the size, material, configuration and other factors of the mixer. Generally speaking, the price range is wide, ranging from a few thousand dollars to hundreds of thousands of dollars.

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English