Mobile Material Surface Feeder

Product Description

Surface Feeder

Introduction

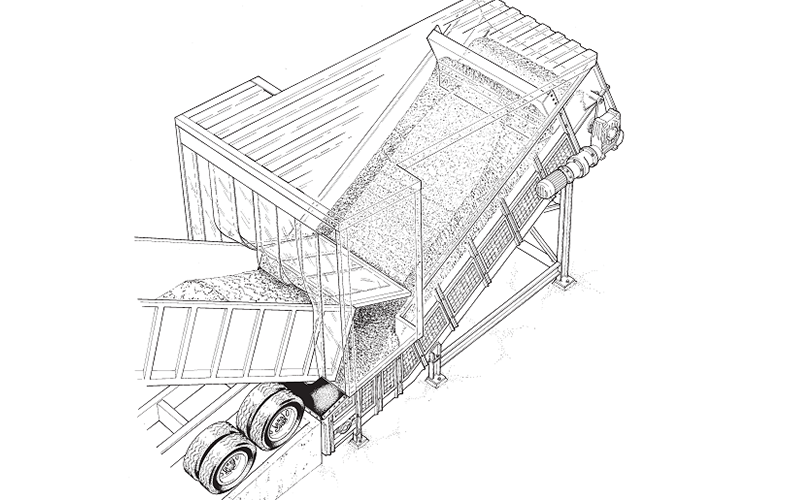

Mobile Material Surface Feeder is developed to meet the user’s need for mobile material receiving and anti-leakage. The equipment can reach the capacity up to 1500t/h, max belt width 2400mm, max belt length 50m. According to various materials, max upwards inclination degree is 23°.

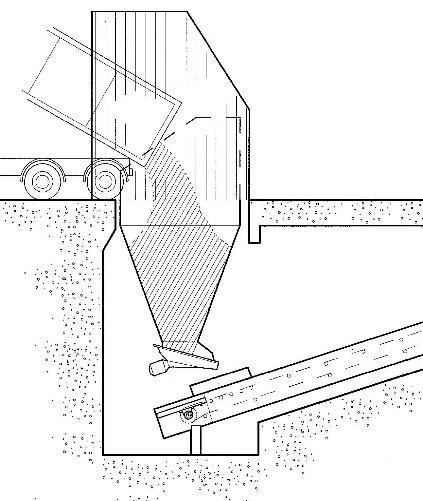

In the traditional unloading mode, the dumper is unloaded into the feeding device through the underground funnel, then transferred to the underground belt and then transported to the processing area. Compared with the traditional unloading method, it has the characteristics of no pit, no underground funnel, no high civil construction cost, flexible setting location, integrated whole machine and so on.

From a functional point of view, the equipment can be divided into parallel feeding section and upward feeding section (according to the actual situation upward feeding section can also be arranged in parallel).

The equipment can be placed directly on the ground to accept incoming materials from trucks.

The equipment chain plate is covered with belt to prevent material leakage, and the fences on both sides are also sealed to prevent side leakage.

Structure:

The equipment is composed of driving device, spindle device, tensioning shaft device, chain plate device (including chain plate and tape), chain, frame,baffle plate(sealed cabin), leakage proof device, etc.

Independent feeders are usually equipped with direct motor drive to cooperate with parallel or orthogonal shaft reducers installed on the extended shaft of the head. In special applications, tandem reducers or hydraulic drives can be used.

Features :

·Low cost

·High efficiency

·Environmental friendly

·Anti leakage

·Without civil work,flexible application site

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English