High-pressure briquetting machine

Product Description

Briquetting machine

High-pressure briquetting machine is a kind of pelletizing machine which can feed various kinds of dry and wet powder through the preliminary pressure device compulsorily into the roller press area and make into high bulk density briquettes. It is mainly applied in the coal, mining, metallurgy, fire-resistant materials, construction materials and other light metal industries.

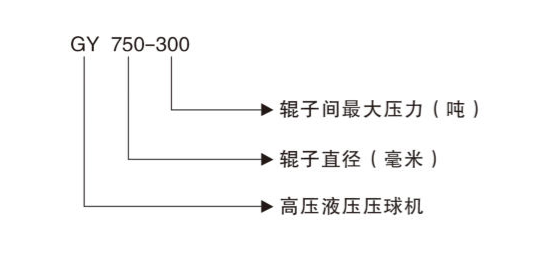

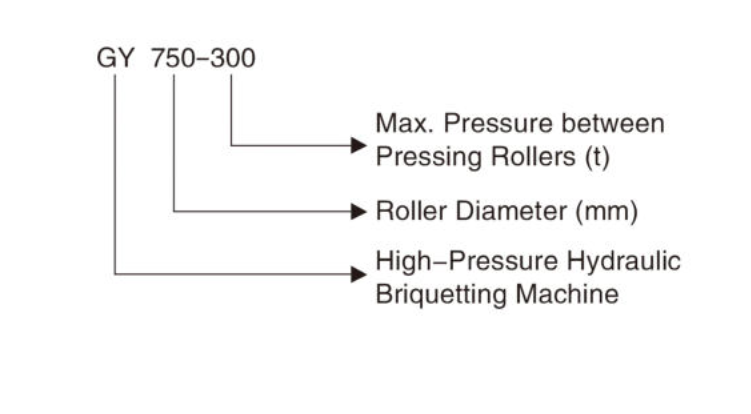

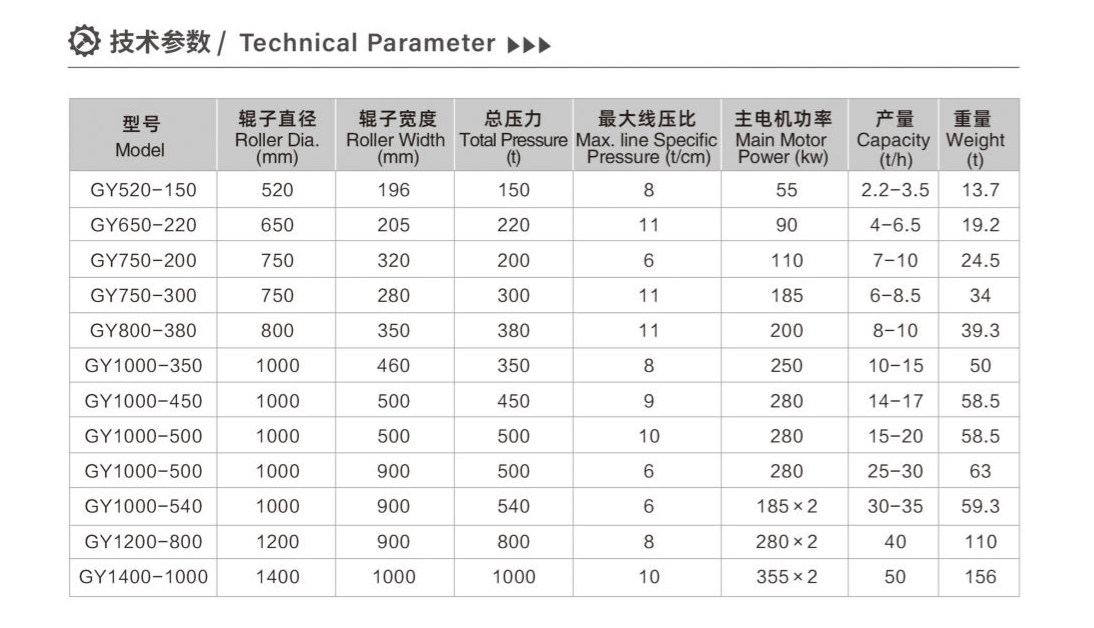

Since the first large high-pressure briquetting machine GY750-300 was trial-manufactured in 1989, our company has formed three series with more than 20 models after years of research, testing and improvement. The machine has reached the international advanced level in terms of structure, performance, quality and service life.

Our company has become a professional factory integrated development, research, testing, design, manufacture and service. It is equipped with complete testing machine and laboratory. We can confirm the process flow, process parameters and finish model-selecting, design and manufacture of briquetting machine based on the briquetting test on the raw materials that provided by users.

Advantages and Features

1.Good pressing effect on materials, high briquetting ratio and high strength of final briquettes.

2.Excellent working effect of the roller surface, with a long service life.

3.Dual-output-shaft reducer is adopted, which effectively improves the roller precision.

4.Hard-tooth surface gears to improve the performance and working life of the reducer.

5.The pre-presser adopts a speed-regulating motor.

6.All wear parts are surfacing welded with wear-resistant alloy to improve working performance and service life.

7.The hydraulic station is placed independently with the function of pressure-adjusting and over-pressure protection.

Order Notes

1.The machine is supplied as right-installed generally. Please specify in the contract if it needs to be installed as left.

2.The capacity and energy-consumption are related with the factors such as material characteristics, size of finished products. The capacity in the parameter table is calculated based on the density of bauxite in standard briquette size of our company.

3.Ordinary motor will be provided for main machine. Please specify in the contract if variable frequency motor is required.

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English