Which is better: Cone Crusher or Jaw Crusher?

Which is better cone crusher or jaw crusher

Cone Crusher

Jaw Crusher

In the realm of industrial material processing, the age-old debate between Cone Crushers and Jaw Crushers continues to spark interest among professionals seeking the most efficient and effective equipment for their crushing needs. While both types of crushers have their loyal followers, the question remains: Which is truly better?

Jaw Crushers have long been recognized for their robustness and simplicity, making them a popular choice for primary crushing applications. Their design features two jaws—one fixed and the other moving—that mimic the motion of a beast's chewing mechanism, capable of handling large feed sizes and high crushing ratios. This makes them particularly well-suited for breaking very hard or abrasive materials, where their brute force approach is a significant advantage.

On the other hand, Cone Crushers operate on a different principle. They utilize a rotating mantle that presses against a stationary bowl liner to compress and fracture the material. This design allows for a more consistent product size and a higher degree of material reduction in a single pass, characteristics that make cone crushers preferable for secondary and tertiary crushing tasks. However, traditional cone crushers rely on mechanical adjustments to control the output size, which can limit their versatility compared to newer hydraulic variants.

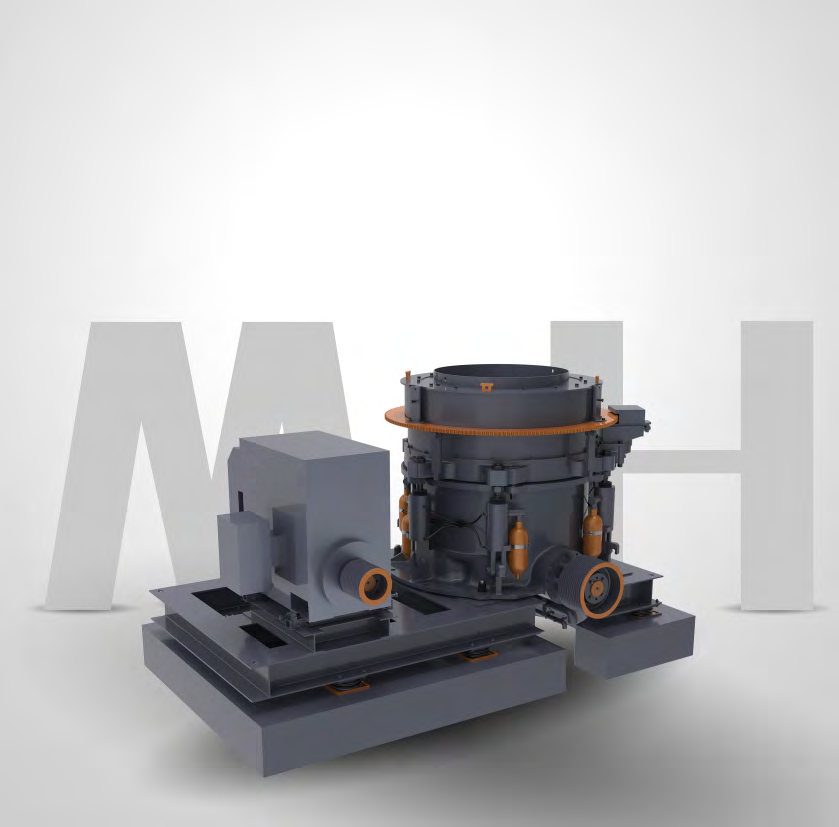

The debate between cone crushers and jaw crushers has intensified with the introduction of advanced Multi-Cylinder Hydraulic Cone Crushers. These state-of-the-art machines incorporate multiple hydraulic cylinders, offering unparalleled control over crushing force and clearance. This precision not only ensures that the end product's size distribution is precisely within desired parameters but also makes them ideal for applications requiring a high degree of accuracy.

Moreover, Multi-Cylinder Hydraulic Cone Crushers boast increased efficiency due to their ability to handle larger feed sizes and generate significant crushing force. This boosts productivity while extending the equipment's lifespan by reducing strain on its components. The hydraulic system's user-friendly interface also simplifies operation and adjustments, ensuring consistent performance under variable load conditions.

So, which is better? The answer lies in the specific requirements of the application. For heavy-duty, primary crushing of extremely hard and abrasive materials, Jaw Crushers remain an excellent choice. However, for projects demanding precise control over product size and quality, along with the ability to handle varied materials effectively, Multi-Cylinder Hydraulic Cone Crushers are emerging as the superior option.

As technology evolves, so too does the landscape of material processing. With advancements like the Multi-Cylinder Hydraulic Cone Crusher, the balance is tipping in favor of cone crushers for those seeking the cutting edge in precision and efficiency. Professionals looking to capitalize on the latest technology now have a compelling reason to lean towards sophisticated hydraulic cone crushers, marking a shift in the traditional cone versus jaw crusher debate.

O'zbek

O'zbek slovenský

slovenský Azərbaycan

Azərbaycan Қазақ

Қазақ Latine

Latine ລາວ

ລາວ български

български नेपाली

नेपाली فارسی

فارسی Javanese

Javanese Українська

Українська Lietuvos

Lietuvos Română

Română Slovenski

Slovenski پښتو

پښتو Punjabi

Punjabi Bosanski

Bosanski Malti

Malti Galego

Galego Afrikaans

Afrikaans Esperanto

Esperanto 简体中文

简体中文 Српски

Српски मराठी

मराठी Ελληνικά

Ελληνικά čeština

čeština Polski

Polski ไทย

ไทย Nederlands

Nederlands Italiano

Italiano Tiếng Việt

Tiếng Việt Deutsch

Deutsch français

français русский

русский Português

Português Español

Español 한국어

한국어 Svenska

Svenska Malay

Malay اردو

اردو norsk

norsk Indonesia

Indonesia عربى

عربى Gaeilge

Gaeilge Türk

Türk Pilipino

Pilipino हिन्दी

हिन्दी Dansk

Dansk বাংলা

বাংলা English

English

What Causes Excessive Wear on Conveyor Belt Edges and How to Prevent It

Excessive conveyor belt edge wear—caused by misalignment, uneven loading, worn rollers, or debris—can be minimized through proper alignment, even material distribution, regular maintenance, and protective measures like skirting and edge guards.

Read MoreHow to Stop Belt Conveyor from Tracking Off-Center (Running Sideways)

Belt conveyors are essential components in industries ranging from mining and manufacturing to logistics and warehousing. However, one of the most common operational issues faced by facility managers and engineers is belt misalignment, often referred to as tracking off-center or running sideways. This problem not only reduces efficiency but can also cause excessive wear, damage to components, and potential safety hazards. Understanding the causes and solutions is key to maintaining smooth conveyor operations.

Read MoreRotary Scraper for Belt Conveyor Sees Growing Use in Industrial Bulk Handling

As industries worldwide continue to automate material-handling processes, the Rotary Scraper for Belt Conveyor has become an increasingly common component in production facilities. Designed to remove residual material from conveyor belts, rotary scrapers are enhancing operational efficiency, reducing downtime, and improving product quality across multiple industrial sectors.

Read More